In the heavy machinery sector, the undercarriage system of excavators is crucial for optimal performance and reliability. Among the essential components of this system, OEM quality BD2G carrier rollers play a significant role. This blog post will delve into what makes these carrier rollers indispensable, highlighting their features, benefits, and applications, while emphasizing the high-grade materials—50Mn and 40MnB—that contribute to their superior performance.

What Are Carrier Rollers?

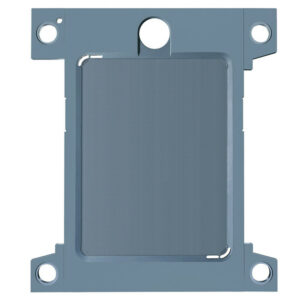

Carrier rollers from Carrier Roller Manufacturer are vital components of the undercarriage in track-type vehicles, including excavators and bulldozers. Their main function is to support the weight of the machine while maintaining proper track alignment and tension. This ensures smooth movement across various terrains, enhancing the overall stability and efficiency of the equipment.

The Significance of OEM Quality in BD2G Carrier Rollers

OEM stands for Original Equipment Manufacturer, and OEM quality BD2G carrier rollers are manufactured to the exact specifications set by the original manufacturer. This guarantees compatibility and performance that aftermarket parts may not always deliver. Here are some key features that characterize OEM quality BD2G carrier rollers:

Key Features of OEM Quality BD2G Carrier Rollers

- High-Grade Materials

OEM quality BD2G carrier rollers are made from high-grade materials like 50Mn and 40MnB steel. These materials offer exceptional strength and durability, enabling the rollers to withstand heavy loads and resist wear in demanding conditions. - Precision Engineering

Each BD2G carrier roller is engineered with precision to ensure a perfect fit and optimal function within the excavator’s undercarriage. This meticulous engineering minimizes friction and results in smoother operation. - Durable Surface Coating

Many OEM carrier rollers feature protective coatings that enhance their resistance to corrosion and environmental factors. This protection is crucial for maintaining high performance, especially in harsh working conditions. - Compatibility

BD2G carrier rollers are designed specifically for compatibility with a range of excavator models. This ensures that operators can seamlessly integrate these rollers into their machinery, eliminating concerns about fit or functionality. - Quality Assurance

OEM parts undergo rigorous quality control processes, ensuring they meet the high standards set by the original manufacturer. This commitment to quality translates into higher reliability and fewer breakdowns.

Benefits of Using OEM Quality BD2G Carrier Rollers

- Enhanced Durability

The combination of high-grade materials and precision manufacturing ensures that OEM quality BD2G carrier rollers are exceptionally durable. Operators can expect a longer lifespan from these rollers, reducing the frequency of replacements and maintenance costs. - Improved Performance

The precise engineering and high-quality construction of BD2G carrier rollers lead to improved performance in excavators. By maintaining proper track alignment and tension, they facilitate more efficient movement and operation. - Increased Reliability

OEM quality BD2G carrier rollers are known for their reliability. This resilience translates to fewer breakdowns and operational failures, which is crucial in industries where downtime can result in significant financial losses. - Cost-Effectiveness

While OEM parts may come with a higher upfront cost than aftermarket alternatives, the long-term savings in maintenance and operational efficiency make them a cost-effective choice. Their durability means fewer replacements and repairs over time. - Enhanced Safety

Well-functioning carrier rollers are essential for the overall safety of heavy machinery operations. By ensuring that tracks are properly aligned and tensioned, OEM quality BD2G carrier rollers help reduce the risk of accidents.

Applications of BD2G Carrier Rollers

OEM quality BD2G carrier rollers find applications across various industries, where their reliability and performance are essential for successful operations:

- Construction

In the construction sector, BD2G carrier rollers are commonly used in excavators and other heavy machinery. Their ability to support tracks efficiently allows for smooth movement and lifting of heavy materials. - Mining

The mining industry demands robust equipment capable of operating in harsh conditions. BD2G carrier rollers are well-suited for use in mining machinery, helping navigate uneven terrains and supporting heavy loads. - Landscaping

In landscaping and earth-moving projects, BD2G carrier rollers ensure that machinery operates smoothly over varying ground conditions. Their reliability is crucial for achieving desired project outcomes. - Agriculture

Agricultural machinery, such as tractors and harvesters, can also benefit from OEM quality BD2G carrier rollers. Their stability and support allow for efficient operation in fields and farms. - Forestry

In forestry operations, BD2G carrier rollers assist in the movement of equipment used for logging and land clearing. Their durability is essential for handling the challenges of rugged terrains.